The PneuTech RDA Variable Speed Dryer features a vertical heat exchanger that handles super-high temperatures, has a large condenser that maximizes performance, and an energy-efficient refrigeration compressor. The VSD on the compressor allows the unit to react to demands. KW consumption syncs with your compressed air dew point demand. The large touch-screen display monitors the pressure and operating temperature, calculates the heat load and adjusts the rotation speed of the compressor and fans. Also capable of remote control with the RS485 interface that comes standard. Combined with the variable speed fan drive, the RDA Variable Speed Dryers offer significant energy savings.

Brochure for RDA Variable Speed Dryers 800-6000 CFM

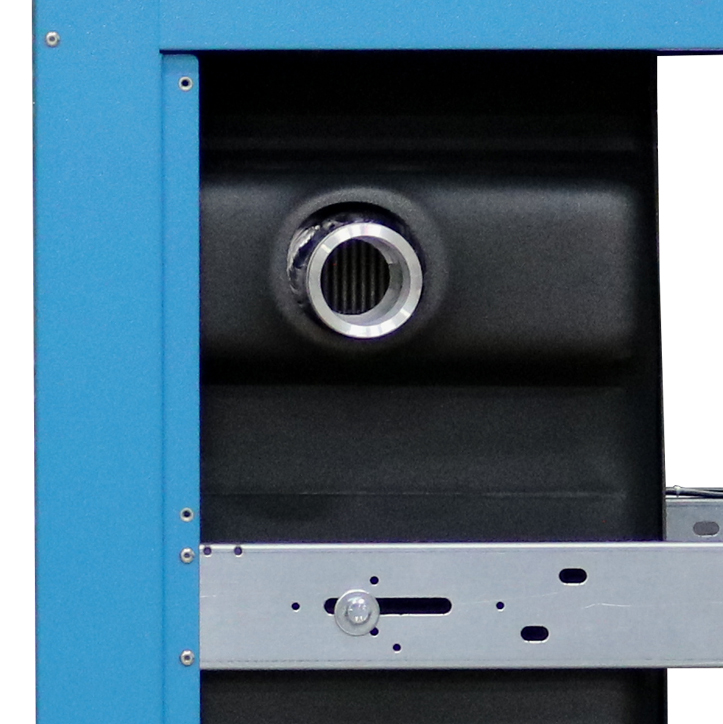

Vertical Heat Exchanger Design – The ALU-DRY aluminum heat exchanger module has a vertical flow layout, ensuring the wet compressed air flows down and moisture is pulled by gravity to the automatic drain. The design of this heat exchanger can handle much higher temperatures than most competitive designs.

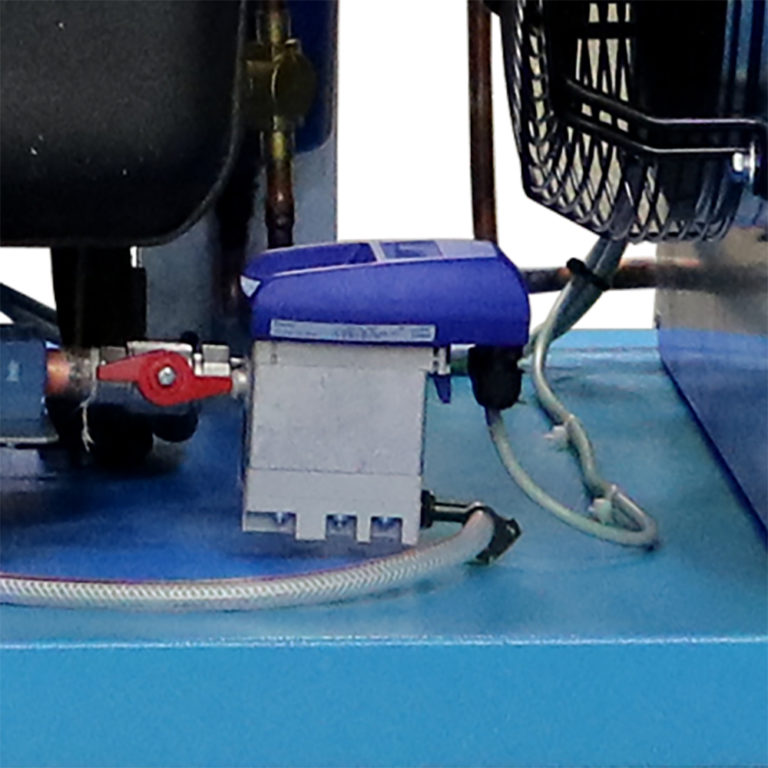

Zero Loss Air Drain – RDF-VSD dryers are equipped with a zero loss drain valve which is operated by the programmable controller. This drain is designed for economical removal of unwanted water, oil emulsions, and other liquids. Drain will only open when liquid is present and will not allow any compressed air to escape from the system.

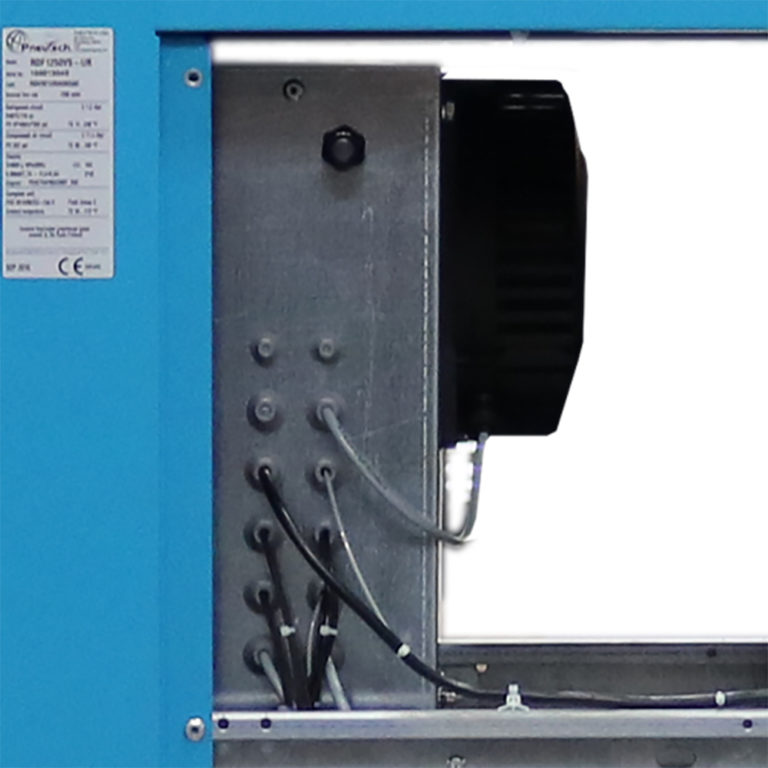

Condenser Fan/Coils – Generous sizing of the condenser unit ensures maximum performance of the refrigerant circuit and the ability to operate with changes in ambient conditions quickly. Access to the condenser for cleaning and maintenance is simple.

Refrigeration Compressor – The circulation of the refrigerant in the cooling system is done through the highly efficient refrigerant compressor. Thanks to its innovative construction, this has reduced energy consumption and increased reliability levels.

Variable Speed Drive Refrigeration Compressor – The VSD feature on this dryer allows the refrigeration compressor to speed up and slow down to meet periods of both high and low demands, without using any excess energy. The dryer operates off of a set target dewpoint rather than cycling between a range of refrigerant pressures. This produces a consistent dewpoint which means consistent production results. As opposed to full voltage motor starts on most fixed speed dryers, the VFD drive initiates slow motor starts which significantly lowers the electrical demand. Up to 75% turndown, allows for a wide range of efficiency. Unlike a standard dryer, KW consumption stays on par with your compressed air dew point demand, resulting in significant energy savings.

Variable Speed Drive Fan – The condenser fan on the dryer is also controlled with a variable speed drive. This allows for the condenser fan to speed up and slow down as refrigerant pressure changes, thus saving on energy costs.

Electronic Controller – DMC 50 controller continuously monitors the pressure and operating temperature, calculates the heat load and adjusts the rotation speed of the compressor and fans. Large touch screen display shows current operating parameters, hour meter, scheduled maintenance, alarm memory, energy savings, and more! Remote monitoring of the dryer is made possible because of the RS485 interface that comes standard with all VSD dryers.