Serial Number - AB00030313

Installation - $3,000

General Features

- Rubber coated pressing rollers before and after working unit

- 1 HP Inverter variable speed feed unit. Feed speeds set at 10 to 60 feet per minute

- Y-Delta two-stage reduced voltage starter on main motor

- 2 roller Infeed and outfeed table extensions

- Automatic Electronic Table Positioning Device

- Adjustable sanding drum and pad position for micro precision adjustment

- Electronic digital thickness readout of work table position

- Powered table lifting by means of four heavy duty motor and lifting columns double fastened at both top and bottom of the lifting columns to provide exceptional table stability

- Electronic tracking of abrasive belt

- Automatic feed mat tracking

- Pneumatic belt tensioning with center fulcrum to compensate for tapering of abrasive belt

- Front and rear emergency stop buttons

- Automatic emergency stop of machine for:

- sanding belt breaking, tensioning, over tracking

- opening of the access door to the operating groups

- absence of compressed air

- overload on main motors

- Amperage meter for main motors allows maximum utilization of available horsepower

- Main disconnect switch with the ability to be locked out by padlock

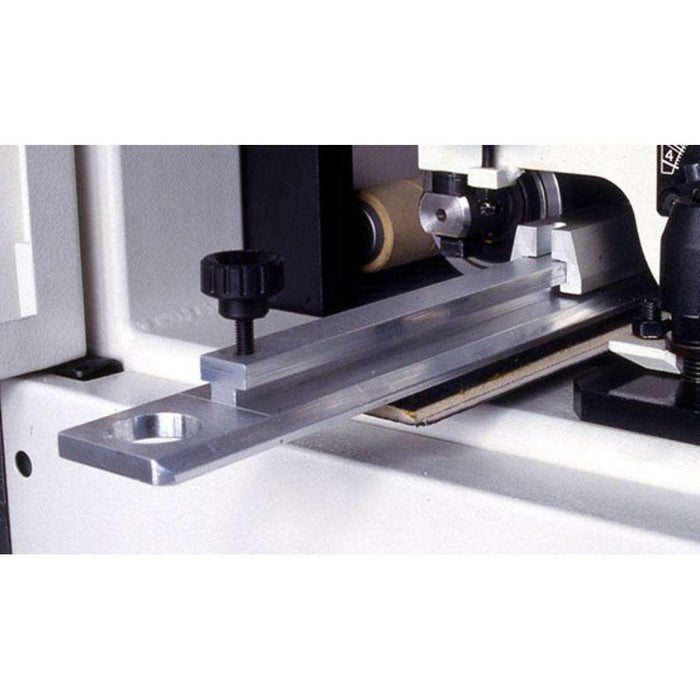

- In feed flexible steel hold down, and anti-kickback plate

- 50 shore, negative profile (waffle style) rubber feed mat

- LOGIC 50 K Electronic Programmer for timing/anti-dubbing of the pad

“Mesar” sectional pad: the best finish with any material. Higher quality results due to the special shape of the sectors that allows the operator to intervene “softly” but also in an “aggressive” way, simply by varying the working pressure. The setting of the pad position and the possibility of using foils of different thickness increases its versality.

“Logic SC” electronic programmer: Easily avoid mistakes. Simple and intuitive, allowing the operator to set all processing parameters in sequence and then launch them with the touch of a button. The possibility to store various work programs to retrieve the machine settings most commonly used makes it ideal even for unskilled operators.

Diamond-shaped belt: No slipping of the work pieces. The special geometry of the diamond-shaped profile of the transport belt provides the best traction surface for the work piece and with the increased support area also ensures maximum stability.

Led indicator for panel introduction. Simple and intuitive, communicating to the operator where and when the panel has to be introduced into the machine and optimising the standard wear of the sanding belt; this ensures a better quality finish and reduced machine costs.

Technical Specifications

|

Model |

DMC SD 30 RCS 95 |

|

|

Working Width |

950mm (37”) |

|

|

Number of Heads Available |

2 |

|

|

Feed Motor |

1 HP Inverter |

|

|

Feed Speed |

15 or 30 fpm |

|

|

Maximum Work piece Thickness |

170 mm (6.69”) |

|

|

Minimum Work piece Length |

12.5 inches |

|

|

Abrasive Belt Size |

37” X 75” |

|

|

Compressed Air Requirements |

6 Bar (88 PSI.) |

|

|

Dust Outlets |

2 outlets @ 140mm (5.5”) |

|

|

Exhaust Requirements |

1,800 CFM |

|

|

Power Requirements |

80 amps @ 230 Volts/3 phase |

|

DMC SD 30 RCS 95 - 37" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE COMBINATION HEAD

SCM DMC SD30 WIDE BELT SANDER VIDEO

This video is for the Sandya 300 which demonstrates the sanding units featured on the DMC SD 30 sander.

SCM DMC SD 30 WIDE BELT SANDER BROCHURE