The Mini Plus One-Arm Spray Machine is the perfect solution for those who have sprayed by hand until today. The automatic through-feed spraying machine mod. MINI achieves the advantages of automatic spraying process with a limited investment. Plug & Spray or stand-alone. All the Advantages of the automatic spraying in a small, efficient, and easy cabin. The price is very competitive, ensuring shipment and installation costs remain low. The machine can also be equipped with a speedy cup on the spraying arm for small batches.

CONVEYING SYSTEM AND PAPER PROTECTION DEVICE

In-feed and out-feed driven roller conveyor system.

Central belt conveyor with protective paper device.

The paper function is to absorb the overspray, thus protecting the conveyor belt underneath.

The machine is equipped with a paper roll unwinding system at the in-feed and rewinding system at the out-feed.

SPRAYING ARM AND LACQUER CIRCUITS

Lacquer application system consisting of a reciprocator with single arm driven by brushless motor and sliding on a high precision linear guide.

Accurate motion guaranteed by high precision reducer.

The arm is equipped with guns holder supporting up to max four guns, with two lacquer circuits. To achieve a higher level of flexibility, the MINI features, as standard, the QUICK-CHANGE system for the guns holder.

2 atomizing manometers placed on the outside of the cabin, each to control 2 guns.

Based on the type of product as well as the grammage to be applied, it is possible to use three different types of guns (not included in the supply); Low pressure guns, Airmix guns, or Airless guns

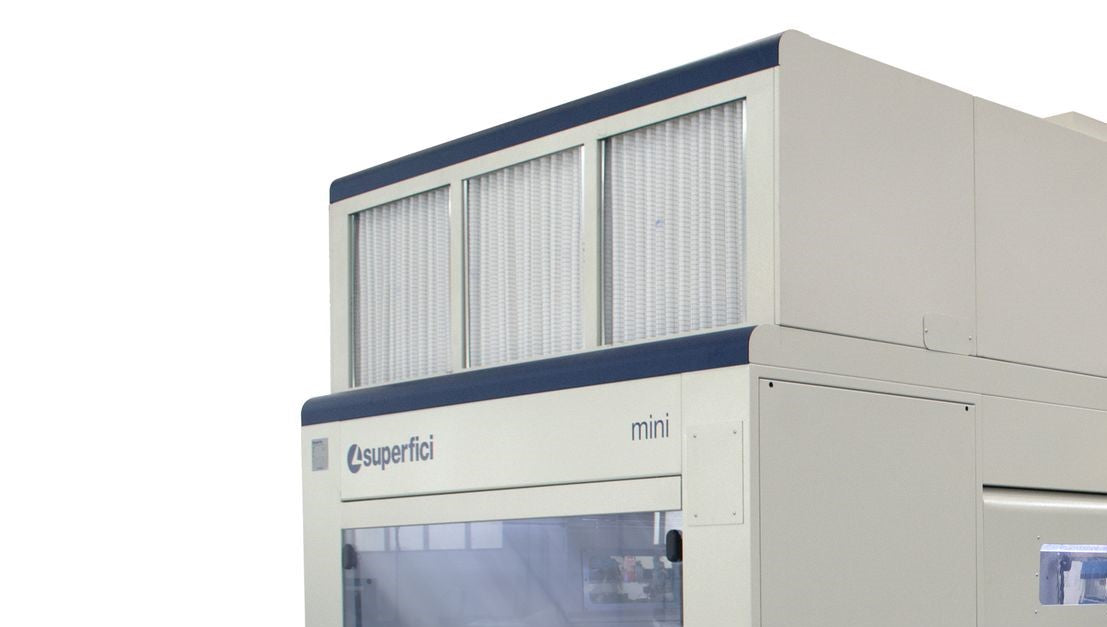

ENCLOSING CABIN

Controlled spraying environment thanks to the enclosing cabin with a highly efficient double side air suction system with dry filters.

Perfectly balanced suction air flow thanks to separate exhausts for the left and right filter tanks.

Filtration by means of double stage dry filters.

The cabin is also equipped with an inspection window on the workpiece infeed and out-feed.

The machine structure integrates all necessary items: control cabinet, exhaust fans, pump support.

The automatic detection of the required working width along with the PLC control allow the reduction of lacquer consumption and achieves consistency in the quality results.

"B&R" PLC control with 5.7” color touch screen mounted on board of the machine, to set and control the automatic spray guns opening and closing in agreement with the conveying speed and with the recognized necessary working width.

Easy to use control software OPTISPRAY.

PRESSURIZATION SYSTEM

The pressurization system consists of two air intake blowing fans combined with a prefiltering system located on the two sides of the cabin, allowing easy access for inspection, as well as a filtering roof inside the booth.

READING BAR

Reading bar as an alternative to the side sensors; a full reading bar across the entire width to identify the spaces between side-by-side panels or any windows.

SPECIAL EXECUTION OF THE PAINT CIRCUITS FOR AUTOMATIC COLOR CHANGE INCLUDES

3 closed loop material circuits (6 hoses) for 3 different coating materials.

1 open end circuit (1 hose) for cleaning agent (solvent flush).

4 automatic color change valves, controlled by 4 solenoid valves, mounted on the reciprocator arm (3 colors + flush).

PLC extension to control the valves.

Software upgrade with user friendly HMI for the control of the automatic sequence of the color change.

10” HMI TOUCHSCREEN

Enlarged touchscreen, for easier human / machine interface.

PRESSURIZATION SYSTEM

The Pressurization System consists of two air intake blowing fans combined with a prefiltering system located on the two sides of the cabin, allowing easy access for inspection, as well as filtering roof inside the booth.

READING BAR

Reading bar as an alternative to the side sensors; a full reading bar across the entire width to identify the spaces between side-by-side panels or any windows.

FLEXIBILITY

Easy management of small batches with frequent color changes. Ability to spray flat or shaped panels. The integrated software recognizes each panel’s dimensions.

The system is integrated with a paper conveyor which rolls and unrolls itself automatically. The lacquer, color change, and gun replacement options are incredibly fast.

Spraying arm installed is on high precision linear guide with brushless motor drive for precise and smooth motion.

GENERAL SPECIFICATIONS Passline Height: 900mm Operating side: RH, as viewed from inlet of line, LH available as a special order. Workpiece Dimensions (Approx.): Min. - max. length: 300 mm - 4880 mm (12" - 16') Min. - max. width: 25 mm - 1300 mm (1" - 51”) Min. - max. thickness: 3 mm - 90 mm (1/8" - 3-1/2") Max. weight: 3# per sq. ft Speeds: Mechanical speed: 1-3 m/min Avg. production speed: 2 m/min Connections: Voltage: 480 V/ 3 Ph + Ground / 60 Hz Standard distribution system: TN-S Compressed air: 6 bars Thermal connection: (NOT required for sprayer – if optional dryer is purchased, the heating coil is electric)

TECHNICAL SPECIFICATIONS Working width: 1300 mm Max. work-piece thickness: 120 mm Working table height: 900 +/- 20 mm Feed speed: 1-3 m/min Compressed air consumption approx: 1800 Nl/min. (with 4 airmix guns) Exhaust air volume: 8000 m3/H Installed power: 9 kW Color grey RAL: 9002 Operating side right hand (left by request) Infeed roller conveyor length: 676 mm Outfeed roller conveyor length: 707 mm Cabin height: 2157 mm Cabin width: 3670 mm Cabin length: 2150 mm Total machine length: 3533 mm Paper roll width: 1600 mm (63") Max. paper roll diam.: 300 mm (11.8") |

SUPERFICI MINI PLUS VIDEO

CUSTOMER REVIEW - ADVANCED MILLWORK SUPERFICI MINI PLUS VIDEO