Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

Click or scroll to zoom

Tap or pinch to zoom

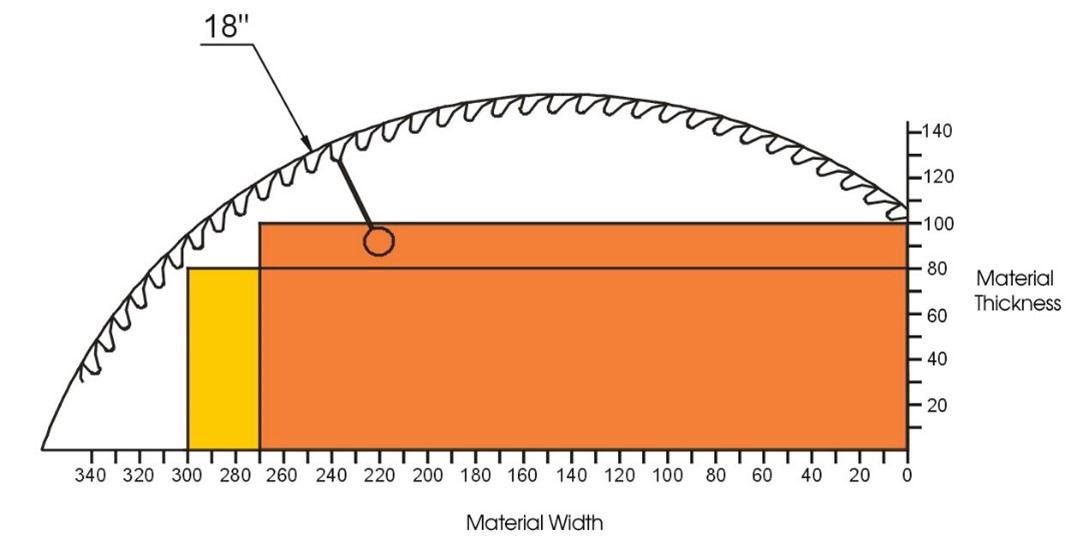

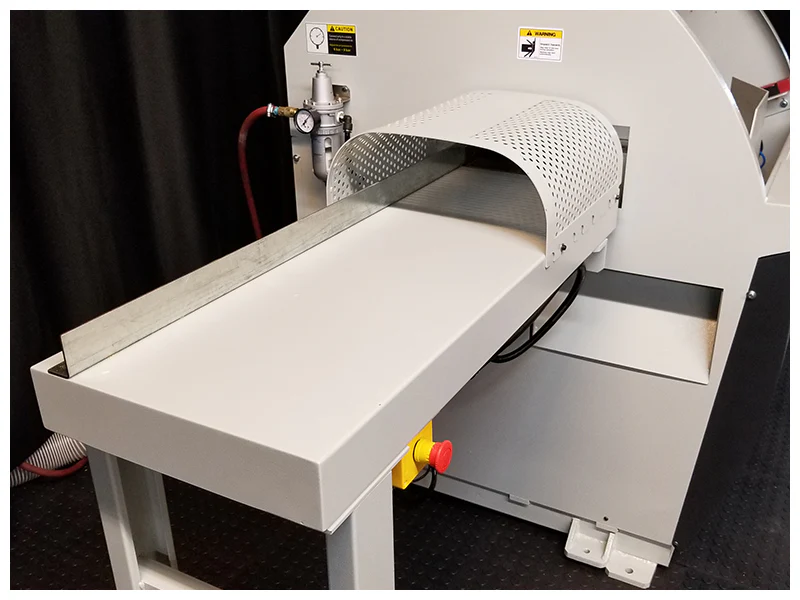

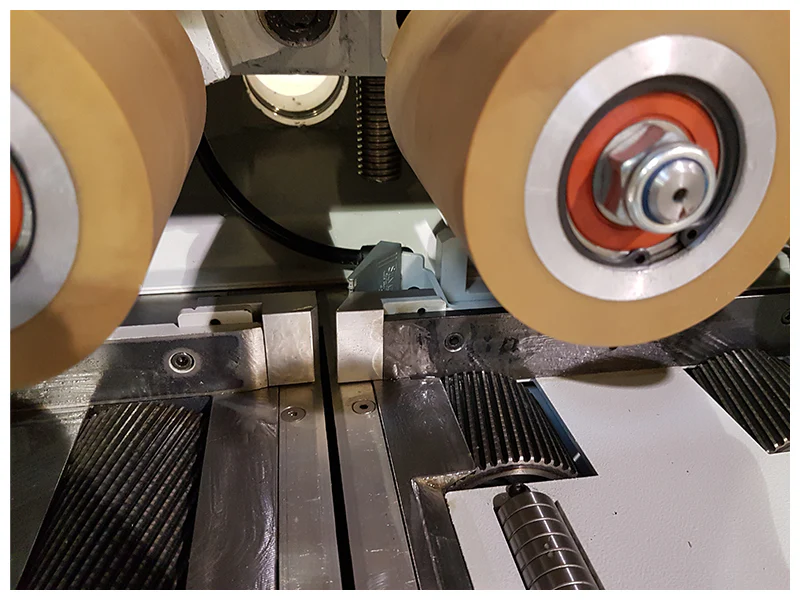

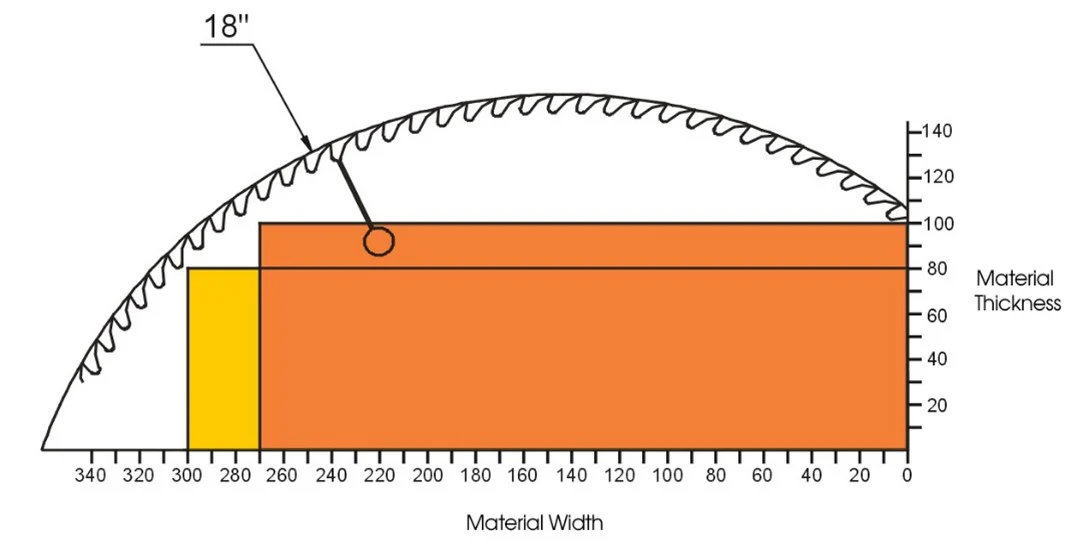

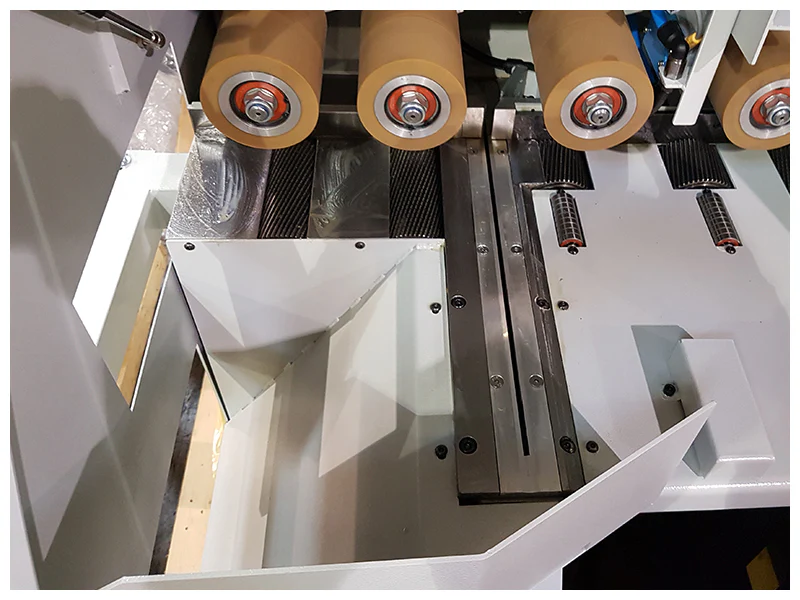

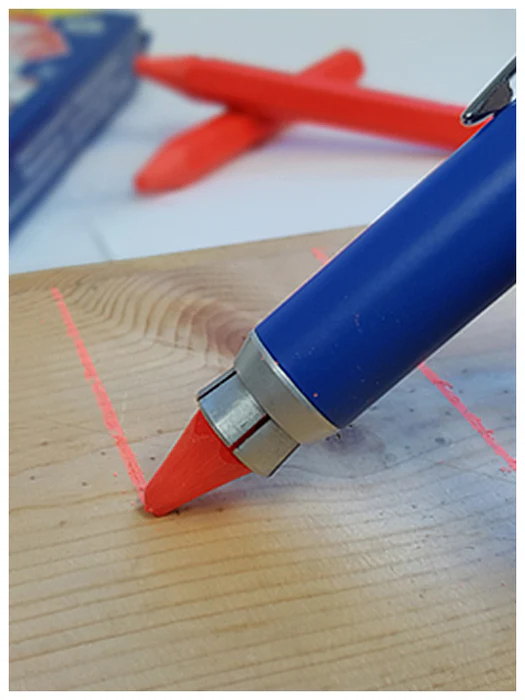

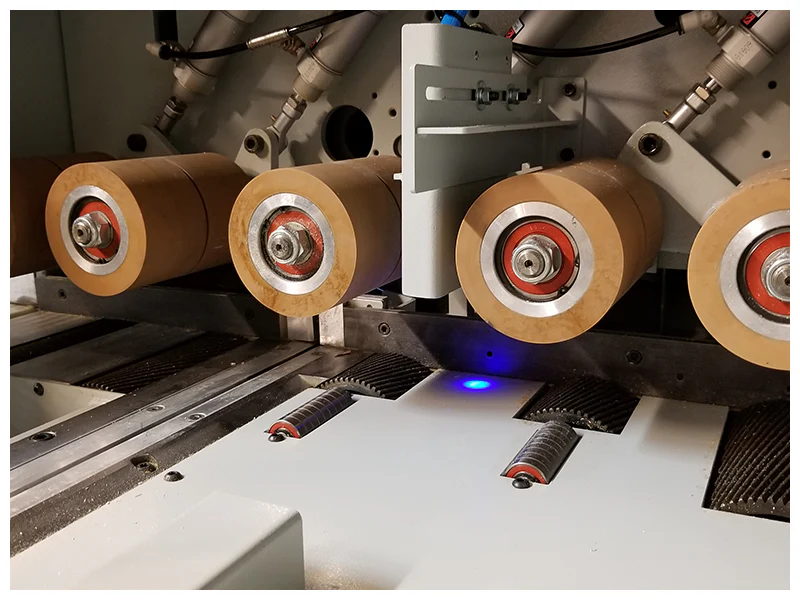

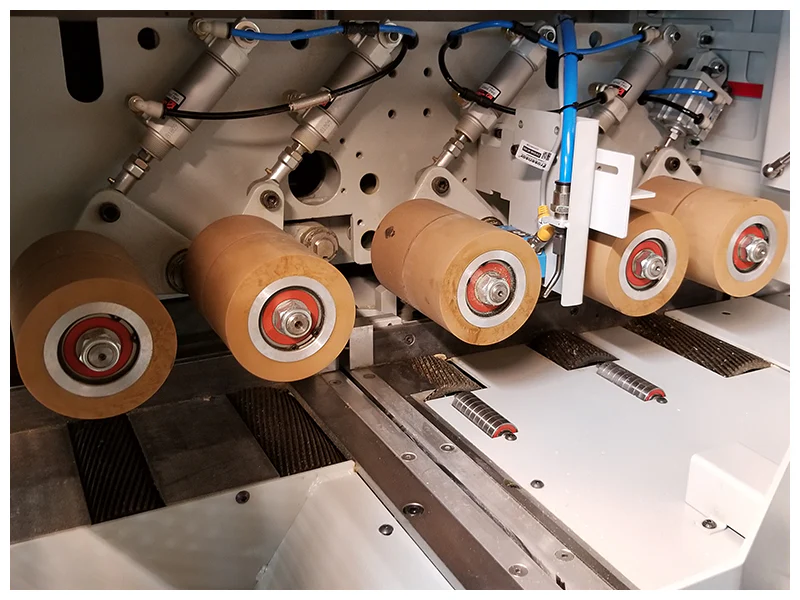

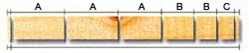

Cantek CFS100 Automatic Defect Cutoff Chop Saw

by Cantek

Sale

$61,600.00

$58,520.00

SKU WSI-CantekCFS100