The only crayon defecting, optimizing saw that drills pocket holes and scribes face frame layout lines, all in one operation! Face frame parts come off the machine ready for assembly.

The RazorOptimal is a programmable saw system that is full of options and power that will deliver what you are looking for. RazorGage combines the RazorGage ST precision with their 18-inch down-cut precision saw, to create a highly accurate, automatic saw system that combines multiple processes into one machine, at a great price point.

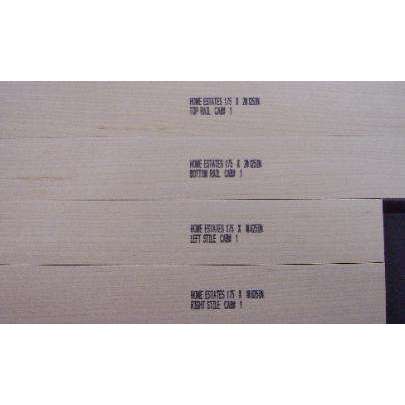

The powerful saw software imports your cutlists and controls the operation. The saw system scans your material for defects, optimizes remaining parts to fit into defect-free areas of your material, automatically advances, cuts lineal stock and prints the part information directly on your material.

This optimizing saw system is capable of producing enough face frame parts for 40 face frames per hour. That’s enough face frames to complete a cabinet order every hour, for the average size kitchen.

· Windows Tower PC operation on a large, color touch-screen monitor.

· Easy to use software. Store 1000’s of cutlists, optimize, sort cutlists into 1000’s of groups according to multiple criteria, and much more.

· Optimizes between crayon marked defects.

· Drills Pocket Holes and Scribes Face Frames

· Automatic top, left and right intelligent clamping

· Paper label printing or print directly on material.

· Part length accuracy varies with application but +/-.005" is possible.

· Optional RazArray sorting light grid can be added to further improve operational efficiencies and reduce mistakes.

RazorGage’s industry leading software is powered by Microsoft Windows so networking and file sharing is no different than any other PC in your office, home, or shop. Since the RazorGage software is based on a rapid development platform, it is constantly evolving to meet the needs of our customers and can be easily customized.

Motor Specs: 7.5 hp (enclosed fan cooled)

Power Requirement: 120 VAC at 10A

Plus one of the following –

· Cyclone Saw: 230 VAC 3φ 30A OR 460 VAC 3φ 20A

· Pockethole Saw: 230 VAC 3φ 40A OR 460 VAC 3φ 30A

Part Accuracy: +/- 0.008"

Push Force: 200 lbs at 10 inches per second

Exhaust Port: Two 4" diameter (102 mm) – minimum 1200 cfm

Compressed Air: Requires 60 psi (5.5 bar) minimum

Minimum Defecting Scanning Width: 1.5"

Maximum Defecting Scanning Width: 12”

Maximum Material Thickness: 1.5"