The new Cut C 200 is the ideal solution for small to medium-sized assembled and kit furniture companies with low to medium productivity requirements for the production of custom-made boxes, different from each other in format and size for batch production or order by order (max flexibility). The packaging is packed on the real dimensions of the product, thus avoiding the use of expensive additional filling materials and related labor time.

Thanks to the longitudinal cutting and creasing units and the transverse unit, it is possible to have great flexibility of box formats and types. The operator can retrieve the desired box from the interface, either by reading a barcode, or by using the scanbox, which transmits the dimensions of the product to be packed to the machine by barcode reading in real time. The cutting and creasing units are the tools needed to create the folds and outline of the cardboard box. The positioning of the longitudinal groups is done sequentially via a positioner installed into the cross group. The machines are equipped with 7 cutting and creasing groups as standard, while a configuration with 12 groups can be chosen as an option to achieve up to 2 boxes side by side.

It is possible to choose from 3 types of carton feeding: single sheet or fanfold, with fanfolds side by side or with automatic selector up to 8 fanfolds (opt.). With the selector, the machine automatically chooses the most suitable size from those available in the infeed to optimize cardboard consumption.

Cut C 200

• Over four boxes produced per a minute

• Carton feeding speed of 45 meters per minute

• Ideal for medium to large-sized assembled and kit furniture companies

• 4 - 5.4 Horsepower (3 - 4 kW)

• Active Box PRO 2.0 software

• Automatic adjustment via panel of groups according to carton thickness

• Longitudinal and transverse perforation as standard (normal creasing and perforated)

• Carton trim management

• Available box designer

• 2500mm maximum usable cardboard width

• 2mm to 7mm Carton thickness

Particularly suitable for:

• Medium-large companies

• Medium to high productivity requirements

• More than 4 boxes per minute

• For batch production or high flexibility (batch 1)

ACTIVE BOX PRO 2.0 SOFTWARE

Enables intuitive management of production and advanced features:

• pre-existing and customizable packaging templates

• customer box archive

• production lists: to plan orders by customer, by product, by period, etc.

• connection with the company network: to manage production from the office or from

the management system.

• production reports and remote SQL queries: report display of various production data.

• available plugins: WEB REPORT

In addition, it includes the following advanced features:

• archive of the types of cardboard used, each with its own optimal working parameters to

simplify the process and obtain consistently perfect boxes

• to the normal 2D and 3D visualizations of box models is now added the animation of the

closure, useful for operators in the case of new or complex models

• fully customizable composite boxes: possibility to create and store packaging consisting of

several parts, for example boxes with protections.

• assisted help with display of the problem solution described on the screen in a PDF sheet.

TECHNICAL INFORMATION

Max usable cardboard width: 2500 mm

Operation: automatic

Productivity: medium - high

Boxes / min: 4

Boxes / day (batch 1): 500 - 1000

Boxes / day (batches): 1000 - 1500

Carton feeding speed: 45m / min

Single carton feeding: fanfold / sheets

Carton storage feeding: up to 8 fanfolds

N. Longitudinal units: 7 to 12

Creasing: normal / perforated

Carton trim management: available

Carton thickness: from 2 mm to 7 mm

Minimum open box length produced: 420 mm

Power supply: 480V / 60Hz (USA)

Power: 4 - 5.4 HP (3 - 4 kW)

Compressed air: min 6-7 bar (max consumption 115 Nl/min)

Operating software: Active box PRO 2.0

Box designer: available

SINGLE

The machine can work with cardboard sheets, single fanfold or both. Cardboard width that can be fed into the machine: minimum 400mm, maximum 2500mm.

MULTIPLE

With this configuration it is possible to use 2 to 4 cardboard fanfolds side by side.

4-LAYERS AUTOMATIC SELECTOR

The multiple storage has 4 layers, each of which can accommodate 2 fanfold side by side, thus doubling the number of available cardboards (up to 8).

SCANBOX

The scanbox allows the machine to read the dimensions of single or several products together and sends the data to the machine for accurate box production. The scanbox can also be used for creating a database with the dimensions of all items. The measurement is done by the operator using the supplied wireless barcode reader by scanning three product dimensions.

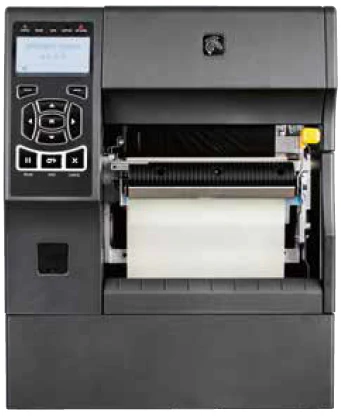

LABEL PRINTER

It is possible to combine the production of the boxes with the printing of the relevant label using a benchtop printer.

SCM CUT C 200 VIDEO