The SCM Class TF 130PS is a versatile, high-performance fixed spindle shaper with an integrated sliding table, designed to enhance precision and efficiency in demanding woodworking applications. Powered by an 11 HP, 3-phase motor (220V), it offers five spindle speeds ranging from 3,000 to 10,000 RPM, ensuring optimal performance for various shaping tasks. The integrated sliding tenoning table, equipped with a miter unit and clamps, provides exceptional control for precise joinery and profiling work. With a generous 42.5” x 29.9” worktable and a 39.25” sliding table stroke, the TF 130PS supports large and complex workpieces with ease. Additional features include a mechanical spindle height readout, reverse rotation switch, aluminum fences, and a foot pedal control for the mechanical brake and spindle lock. Designed for maximum versatility and accuracy, this machine is the ideal choice for professionals seeking power, precision, and advanced shaping capabilities in one compact unit.

STANDARD EQUIPMENT

- Sliding tenoning table with miter unit and clamps

- 1.25” interchangeable spindle

- 5 Spindle speeds from 3,000 to 10,000 rpm

- Reverse rotation switch

- 5 Table insert rings

- 7” Working spindle height below the nut

- “T” Slot in Table with Mitre Gauge

- Mechanical readout of spindle height

- Foot pedal control of mechanical brake and spindle lock

- Magnetic starter with overload protection

- Low tension circuit (110v by transformer)

- Tool kit with spare V-belt

- Aluminum fences

- Adjustable fence and guard assembly

Set up precision and reliability. The operator easily adjusts every movement thanks to the handwheel with mechanical readout positioned on the machine front.

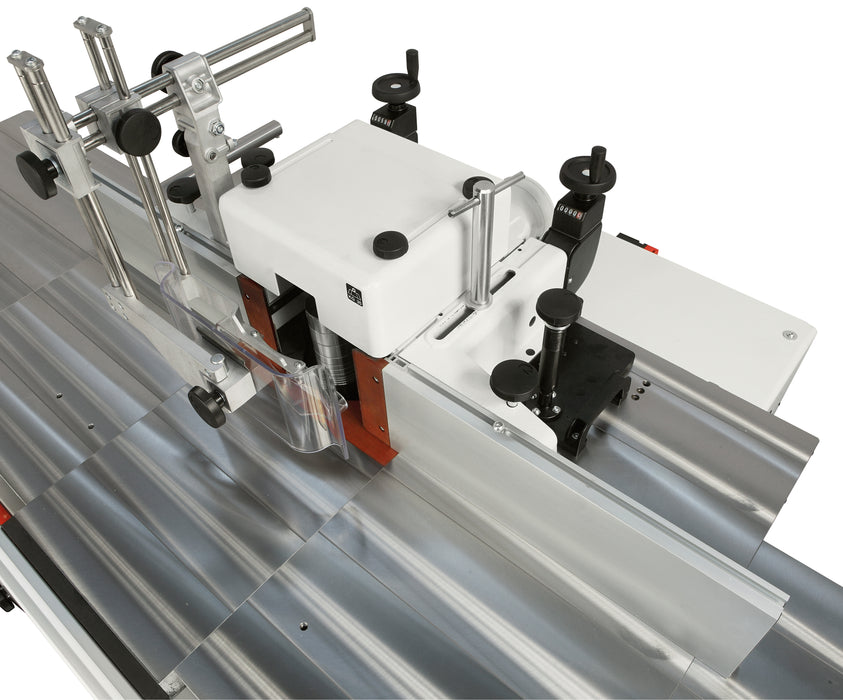

With the front sliding carriage integrated in the table, the table, the tilting telescopic fence and the protection hood with dedicated armguard, the operator can easily and safely carry out tenoning and profiling operations.

Spindle moulder fence with mechanical programming: maximum set up speed and ease-of-use. No more test runs due to digital readouts that ensure accuracy to a tenth of a millimetre in positioning the two worktables

Monoblock Base

Monoblock technology is used in the design and fabrication of this base. The solid, welded base undergoes a treatment call normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

Large Spindle Assembly

One thing that can degrade the quality of finish from a shaper is the vibration transmitted from the spindle to the cutter. Minimizing vibration is even more critical when cutting tall profiles or using stacked tooling. SCM ensures maximum quality in its shapers by using very large spindle assemblies whereby the increased mass of the spindle absorbs vibrations and eliminates whipping action at the top of the spindle. All SCM shaper spindles are completely assembled and high speed balanced as one complete unit which further ensures vibration free performance.

Greater Tooling Flexibility

The Class TF 130PS has a 7-inch tool capacity under the nut. Coupled with the digital indicator for the spindle height, this makes the SCM shapers perfect for the use of stacked tooling. For example, many woodworkers use a tooling package consisting of three cutters for making cabinet doors. The stile, rail, and panel cutters are all mounted on the same spindle. By raising or lowering the spindle, it is possible to perform all three operations without changing the cutter or the spindle. The five speed spindle further increases tooling flexibility.

Integrated Sliding Table

The Class TF 130PS has a unique integrated sliding table that is useful for tenoning and other small profile jobs. It is equipped with stops and hold-downs and can also be set at an angle.

Adjustable Fence

The fence has continuous linear adjustment by a crank that is accessible from the front of the machine. - Total adjustment of fence to tool - Thickness control of cutting stroke - Mechanical readout for the adjustment - Wooden tables and connecting bars - Max. tool diameter 250mm

MACHINE CONFIGURATION