Installation - $4,500

Maximum performance for companies increasing production. Designed for the medium to high industrial companies that require diversified machining, dmc sd 90 satisfies all calibrating and sanding requirements, by offering a wide range of technological solutions allowing the possibility of customising the machines compositions. The availability of offering many types of operating units such as planing units, roller units (with 175, 220, 250 and 320mm diameters), pad units and superfinishing units guarantees the very best results on solid wood, veneer, laquer and paint operations.

General Features

DMC SD 90 RRCS 135 SW & VN - THREE HEAD WIDE BELT SANDER

Base and working table

Steel structure with electric cabinet on the machine front

Sanding belts introduction from the machine left side

Powered adjustment of working thickness

Main motor positioned inside the base

Electrical equipment

Electromechanical keyboard positioned on the machine front side

Automatic star-delta start of the main motor

Overload protections on the motors

Motors in isolation class IP54

Emergency and safety devices

Automatic brake for rapid shutdown of the operating group

Hand-safety emergency device in the infeed panel area

Front and rear emergency pushbutton

Padlockable main switch

Automatic emergency stop machine for:

- Sanding belt breaking

- Not-tensioned sanding belt

- Lateral outplacement of sanding belt

- Absence of compressed air

- Overload on main motor

Basic machine standard equipment

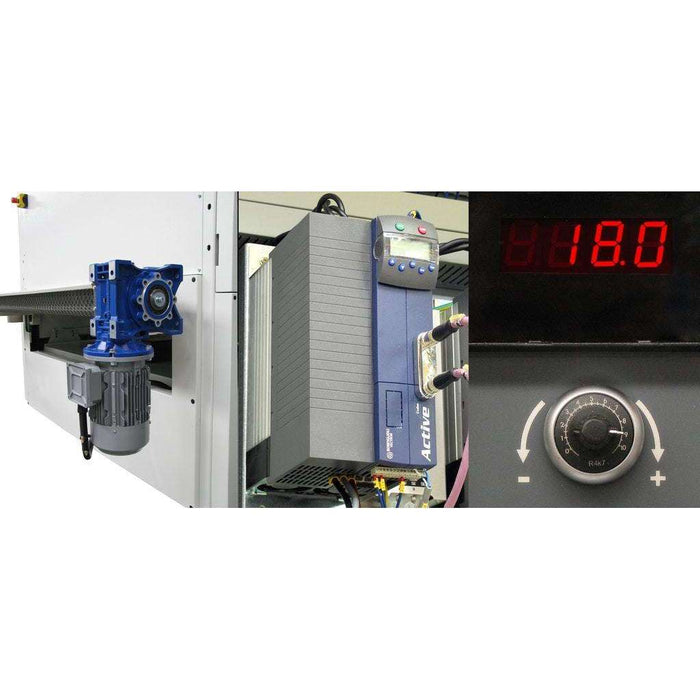

Electronic ammeter on main motor for readout of absorbed power

Electronic readout of working thickness

Electronic oscillating of sanding belts

Rubber-coated pressure rollers

Infeed anti-kickback vertically pivoted roller on 1st operating group

Infeed/outfeed work pieces support rollers with two rollers

Automatic device for feed belt tracking and tensioning

Machine control features

Control of 3 main operating groups

Control of one brushing unit and one outfeed blower unit

Control of vacuum table

Control of on/off positioning and timed intervention of the pad or roller groups

Control of two inverters (on your choice: on the two main operating groups or one inverter on the operating group and one inverter on the feed belt)

Working thickness control

Abrasive belt speed control

Reverse rotation control of one abrasive belt

Sequential automatic start-up of main motors

Blowers timing control for belts cleaning and for rotating blowers of outfeed panel cleaning

Machine control in manual or semiautomatic mode or with 4 working programs selectable or rapidly actable by means of function pushbuttons

Graphic visualization of machine configuration on front

Machine report (working and stand-by hours)

Machine damage alarms control

The possibility to store up to 120 work programs to retrieve the machine settings most commonly used makes it perfect even for unskilled operators.

Technical Specifications

|

Model |

DMC SD 90 RCS 135 SW & VN |

DMC SD 90 RCST 135 VN |

|

Working Width |

1,350mm (53”) |

1,350mm (53”) |

|

Number of Heads Available |

2 |

3 |

|

Feed Motor |

3 HP with inverter |

3 HP with inverter |

|

Feed Speed |

12 to 60 fpm |

12 to 60 fpm |

|

Maximum Work piece Thickness |

170mm (6.69”) |

170mm (6.69”) |

|

Minimum Work piece Length |

12.5 inches |

12.5 inches |

|

Abrasive Belt Size |

53” x 103” |

53” x 103” |

|

Compressed Air Requirements |

6 Bar (88 PSI) |

6 Bar (88 PSI) |

|

Dust Outlets |

2 outlets @ 195mm (7.75”) |

2 outlets @ 195mm (7.75”) |

|

Exhaust Requirements |

3,544 CFM |

3,744 CFM |

|

Power Requirements |

130 amps @ 230 Volts/3 phase |

137 amps @ 230 Volts/3 phase |

Dimensions

|

SCM DMC SD 90 RCS 135 SW & VN |

|

|

Overall Dimensions |

|

|

Height of fixed table |

2260 – 2460mm |

|

Height of mobile table |

2264mm |

|

Width |

1899mm |

|

Length |

2580mm |

DMC SD 90 RRCS 135 - 53" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE RUBBER DRUM ROLLER, ONE COMBINATION HEAD

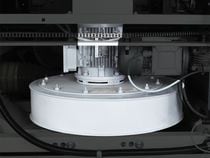

DMC SD 90 RRT 135 - 53" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE RUBBER DRUM ROLLER, ONE SUPERFINISHER ORIBITAL PAD

DMC SD 90 RCST 135 - 53" WIDE BELT SANDER - ONE STEEL DRUM ROLLER, ONE COMBINATION HEAD, ONE SUPERFINISHER ORIBITAL PAD

DMC SD 90 KRCS 135 - 53" WIDE BELT SANDER - PLANER, ONE RUBBER DRUM ROLLER, ONE COMBINATION HEAD

SCM DMC SD 90 | 53" WIDE BELT SANDER VIDEO

This video is for the Sandya RRCS 900 which demonstrates the sanding units featured on various DMC SD 90 sanders.

SCM DMC SD 30, 60, 70, 90 | NEW HMI CONTROLLER VIDEO

SCM DMC SD 90 WIDE BELT SANDER BROCHURE